Image from https://yukaichou.com/gamification-examples/octalysis-complete-gamification-framework/

In the high-stakes environment of chemical processing plants, where safety and compliance are paramount, the assurance and auditing processes play a critical role. However, these essential tasks often face the challenge of maintaining consistent engagement and vigilance. This blog post explores the integration of this gamification principle to enhance the efficacy of assurance and auditing in a chemical processing context.

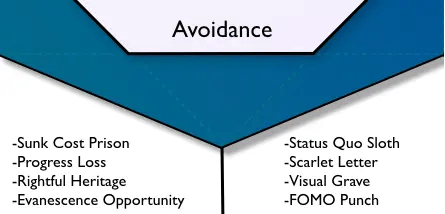

Understanding “Loss & Avoidance”

The “Loss and avoidance” drive in the Octalysis Framework links to the human tendency to avoid adverse outcomes. In assurance and auditing, leveraging this drive can motivate employees to adhere to processes and protocols more diligently, driven by the desire to prevent loss or avoid adverse consequences.

- Penalty Points for Non-Compliance: Introduce a system where teams or individuals accrue penalty points for non-compliance or missed audits. The accumulation of points could lead to additional reviews or the need for retraining, creating a tangible consequence for lapses in assurance processes.

- Visual Displays of Compliance Status: Visual indicators such as red-amber-green (RAG) status boards display compliance levels. The immediate visual representation of slipping into a ‘red’ zone can drive corrective actions more effectively.

- Gamified Compliance Scenarios: Develop interactive scenarios that simulate the consequences of non-compliance or audit failures. These gamified experiences can vividly illustrate potential risks and losses, reinforcing the importance of thorough and accurate auditing.

- Loss Aversion in Auditing Rewards: Structure rewards and recognition programs to include an element of loss aversion. For example, employees could earn certain privileges or bonuses based on compliance, which are at risk of being lost if standards are not maintained.

- Compliance Countdowns: Implement countdowns to important audit deadlines or compliance dates. The timer creates a sense of urgency, prompting teams to avoid the last-minute rush and potential oversights.

- Regular Feedback on Risks and Near-Misses: Provide regular feedback on identified risks, near-misses, or compliance issues. Highlighting near misses can reinforce the importance of vigilance in assurance and auditing tasks.

The Impact of “Loss & Avoidance”

Incorporating “Loss & Avoidance” into assurance and auditing can yield significant benefits:

- Improved Compliance Adherence: The desire to avoid negative consequences can result in more diligent adherence to safety and compliance standards.

- Increased Risk Awareness: Regular reminders of what can go wrong help keep risk management at the forefront of employees’ minds.

- Heightened Engagement with Processes: The dynamic nature of this approach keeps employees more engaged with the assurance and auditing activities.

Conclusion

By applying the “Loss & Avoidance” core drive from the Octalysis Framework to assurance and auditing in chemical processing plants, we can infuse these essential processes with a new level of diligence and engagement. This approach promotes a deep understanding of the importance of compliance and safety and fosters a proactive culture that continuously strives to avoid adverse outcomes. In an industry where the cost of non-compliance can be significant, such a strategic and psychologically informed approach can make a substantial difference in maintaining the highest operational standards.

To learn directly from Yu-Kai’s site:

The information in this article was partially generated by OpenAI’s ChatGPT, an AI language model, and has been reviewed/edited for accuracy and relevance. OpenAI. (2024). ChatGPT [Large language model]. Retrieved from https://chat.openai.com/

Leave a comment