Introduction

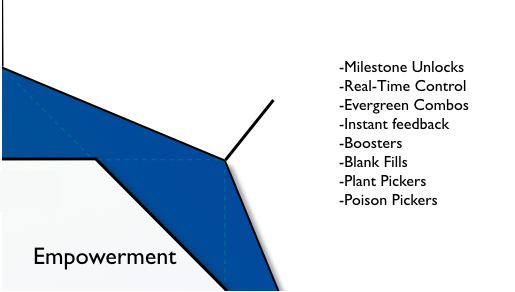

Image from https://yukaichou.com/gamification-examples/octalysis-complete-gamification-framework/

In a chemical processing plant’s structured and procedural world, maintenance is a critical function that ensures operational continuity and safety. However, this crucial area often needs more encouragement of creative problem-solving and active feedback mechanisms. ‘Empowerment of Creativity & Feedback’ core drive of the Octalysis Framework, a renowned gamification strategy developed by Yu-kai Chou, can play a transformative role.

Understanding ‘Empowerment of Creativity & Feedback’

The ‘Empowerment of Creativity & Feedback’ drive encourages individuals to express their creativity and innovation while providing immediate feedback on their actions. This drive enhances engagement and fosters a culture of continuous improvement and learning.

Applying the Core Drive in Chemical Plant Maintenance

- Encouraging Creative Problem-Solving: Maintenance teams often face unpredictable challenges. By encouraging creative problem-solving, team members feel empowered to develop innovative solutions. Workshops and brainstorming sessions can be organized where team members can suggest improvements in maintenance procedures.

- Implementing a Feedback Loop: Establishing a robust feedback system is essential. This could be through digital platforms where team members can submit their ideas and receive constructive feedback. Regular team meetings can also be platforms for discussing feedback and evaluating ideas.

- Rewarding Innovation: Recognize and reward creative solutions that improve maintenance processes. Rewards range from public acknowledgment to tangible benefits like bonuses or additional training opportunities.

- Gamifying the Maintenance Process: Introduce gamification elements in maintenance tasks. For example, teams could earn points for identifying potential system improvements or successfully implementing a new maintenance procedure. Leaderboards or achievement badges can provide visual representations of their contributions.

- Fostering a Collaborative Environment: Create a collaborative environment where maintenance staff can collaborate on problem-solving, facilitating projects that require creative thinking through team-building activities and collaboration.

- Providing Resources for Experimentation: Offer resources such as time, budget, and tools for staff to experiment with new ideas. This could be a ‘sandbox’ environment where employees can test their ideas without the pressure of immediate implementation.

- Continuous Learning and Development: Encourage continuous learning by providing access to , workshops, training programs, and seminars focusing on creative thinking and innovation in maintenance.

- Utilizing Technology for Creative Solutions: Leverage technology to foster creativity. This could include using simulation software to test out maintenance scenarios or employing predictive analytics to identify potential areas of improvement.

Conclusion

Integrating the ‘Empowerment of Creativity & Feedback’ drive from the Octalysis Framework into the maintenance strategy at a chemical processing plant can lead to a more dynamic, innovative, and efficient maintenance process. By empowering teams to be creative, providing them with constructive feedback, and recognizing their innovative efforts, a chemical processing plant can enhance its maintenance operations and cultivate a more engaged and motivated workforce. The result is a maintenance strategy that is efficient, reliable, adaptive, and forward-thinking.

To learn directly from Yu-Kai’s site:

The information in this article was partially generated by OpenAI’s ChatGPT, an AI language model, and has been reviewed/edited for accuracy and relevance. OpenAI. (2024). ChatGPT [Large language model]. Retrieved from https://chat.openai.com/

Leave a comment