Introduction

Image from https://yukaichou.com/gamification-examples/octalysis-complete-gamification-framework/

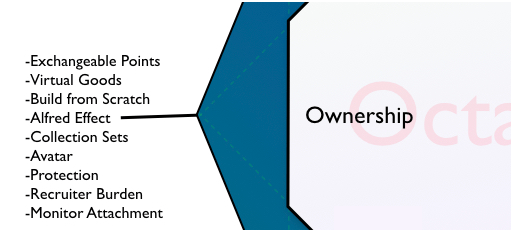

In a chemical processing plant’s highly technical and safety-critical environment, the maintenance strategy and execution are vital for operational success and safety. However, The ‘Ownership & Possession’ core drive of the Octalysis Framework, a gamification strategy created by Yu-kai Chou, offers a new perspective and approach to engaging the maintenance team and instilling a sense of ownership can be a challenge.

Understanding ‘Ownership & Possession’ in the Octalysis Framework

The ‘Ownership & Possession’ drive is about creating a sense of ownership over tasks, projects, or outcomes. This drive makes people care more about what they own, fostering a deeper level of engagement and responsibility.

Applying ‘Ownership & Possession’ in Chemical Plant Maintenance

- Personal Responsibility for Equipment and Tools: Assign specific equipment or tools to individual team members or small teams, creating a sense of personal responsibility for the maintenance and performance of these assets.

- Maintenance Project Ownership: Encourage teams to fully own specific maintenance projects or areas within the plant, including planning, executing, and monitoring maintenance activities, giving them autonomy while holding them accountable for the outcomes.

- Rewarding Ownership: Recognize and reward individuals or teams who demonstrate exemplary care and improvement in their areas of responsibility. Rewards can range from public acknowledgment to bonuses or professional development opportunities.

- Tracking and Reporting Systems: Implement a system where maintenance teams can track and report on their projects through digital dashboards or regular reporting meetings. Visibility of their work fosters a sense of pride and ownership.

- Involvement in Decision Making: Involve maintenance staff in decision-making processes, especially those affecting their work, e.g., selecting tools, planning maintenance schedules, or improving processes.

- Maintenance Knowledge Sharing: Encourage sharing knowledge and best practices among teams through regular meetings, workshops, or digital platforms. When team members contribute their knowledge, they feel a sense of ownership over the shared practices and standards.

- Personal Development Plans: Tie individual development plans to maintenance goals. Allow team members to set personal objectives that align with the broader maintenance strategy, personalizing their role and enhancing their sense of ownership.

- Visualizing Impact: Use visual tools to show the impact of maintenance work on plant performance. Understanding how an individual’s work contributes to the larger picture can reinforce a sense of ownership and pride.

Conclusion

Integrating the ‘Ownership & Possession’ drive from the Octalysis Framework into the maintenance strategy at a chemical processing plant can significantly enhance team engagement and accountability. Maintenance teams can be more motivated by fostering a sense of personal responsibility and pride in their work, resulting in improved maintenance outcomes, operational efficiency, and safety. This approach benefits the plant’s operational goals and contributes to a more satisfied and empowered workforce, driving continuous improvement in the maintenance process.

To learn directly from Yu-Kai’s site:

The information in this article was partially generated by OpenAI’s ChatGPT, an AI language model, and has been reviewed/edited for accuracy and relevance. OpenAI. (2024). ChatGPT [Large language model]. Retrieved from https://chat.openai.com/

Leave a comment