Introduction

Image from https://yukaichou.com/gamification-examples/octalysis-complete-gamification-framework/

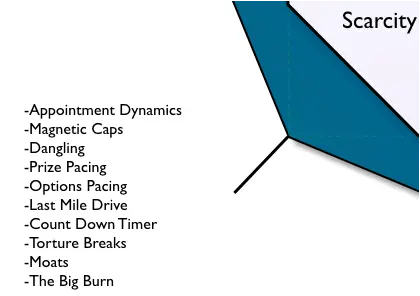

Applying gamification principles can bring about transformative changes in a chemical processing plant, with high stakes for efficient and timely maintenance. One such principle is the “Scarcity & Impatience” core drive from the Octalysis Framework, developed by Yu-kai Chou. When applied strategically, this drive can significantly enhance the maintenance strategy and execution process.

Understanding ‘Scarcity & Impatience’

The ‘Scarcity and impatience’ drive relates to the human psychological response to scarcity and the desire to have something they can’t immediately obtain. This drive can create urgency, prioritize tasks, and improve efficiency in maintenance operations.

Applying ‘Scarcity & Impatience’ in Chemical Plant Maintenance

- Limited-Time Challenges: Introduce limited-time challenges for maintenance tasks. For instance, setting a challenge to complete preventive maintenance checks within a specific time frame can create a sense of urgency and prompt action.

- Exclusive Access to Resources: Offer exclusive access to advanced tools, training, or workshops for those who meet specific maintenance performance benchmarks, creating a sense of scarcity and encouraging staff to strive for excellence.

- Prioritization of Tasks: Implementing a system prioritizing maintenance tasks based on urgency and importance helps manage the scarcity of time and resources more effectively, ensuring prompt completion of critical maintenance tasks.

- Time-Bound Goals with Rewards: Set time-bound goals for completing maintenance projects or tasks. Offering rewards upon timely completion can motivate teams to work efficiently and manage their time effectively.

- Visibility of Progress and Deadlines: Use visual tools like countdown timers or progress bars to highlight deadlines and the progress of maintenance tasks. This constant visibility can create a sense of impatience and urgency, driving teams to complete tasks on time.

- Limited Opportunities for Special Projects: Create opportunities for involvement in special projects or advanced training programs, but limit the number of spots available. This scarcity encourages staff to perform well in their regular tasks to qualify for these opportunities.

- Early Access to New Technologies: Offer early access to new technologies or systems to those who excel in maintenance roles, incentivizing good performance and keeping the team updated with the latest developments.

- Feedback Loops: Establish rapid feedback loops for maintenance tasks. Quick feedback on completed work can create a sense of urgency for continuous improvement and responsiveness.

Conclusion

Integrating the ‘Scarcity & Impatience’ drive of the Octalysis Framework into the maintenance strategy of a chemical processing plant can lead to a more dynamic and responsive maintenance culture. Maintenance teams can become more efficient, proactive, and motivated to excel by utilizing scarcity principles and creating a sense of urgency. This approach enhances the plant’s operational efficiency and contributes to a highly engaged and goal-oriented maintenance workforce.

To learn directly from Yu-Kai’s site:

The information in this article was partially generated by OpenAI’s ChatGPT, an AI language model, and has been reviewed/edited for accuracy and relevance. OpenAI. (2024). ChatGPT [Large language model]. Retrieved from https://chat.openai.com/

Leave a comment