Introduction

Image from https://yukaichou.com/gamification-examples/octalysis-complete-gamification-framework/

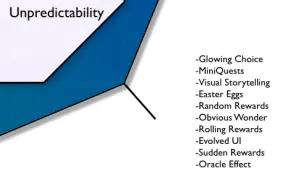

In the rigorous and systematic world of chemical processing, maintenance often follows a predictable, routine path. However, the introduction of ‘Unpredictability & Curiosity,’ a core drive from Yu-kai Chou’s Octalysis Framework, can revitalize maintenance strategies. This gamification principle harnesses the human desire for surprise and the joy of discovering the unknown, transforming mundane maintenance tasks into engaging and dynamic activities.

Understanding ‘Unpredictability & Curiosity’

‘Unpredictability & Curiosity’ is about tapping into our innate desire to resolve uncertainty and the pleasure derived from unexpected outcomes. In a maintenance context, this principle can foster a culture of continuous learning, innovation, and engagement.

Integrating ‘Unpredictability & Curiosity’ in Chemical Plant Maintenance

- Randomized Rewards and Recognition: Introduce a system of randomized rewards for maintenance tasks. For instance, unexpected bonuses or recognition for teams or individuals who exceed maintenance targets or develop innovative solutions can boost morale and engagement.

- Mystery Challenges: Incorporate mystery challenges into the maintenance schedule. These could be unexpected scenarios or simulations that require problem-solving under different conditions, encouraging teams to think creatively and remain agile.

- Surprise Learning Opportunities: Offer surprise learning opportunities, such as unexpected training sessions with external experts or access to new technology workshops, keeping the team curious and eager to learn more.

- Gamified Maintenance Activities: Gamified maintenance activities introduce elements of unpredictability, including mystery problem-solving tasks, where the task details are progressively revealed based on team achievements.

- Interactive Maintenance Platforms: Utilizing digital platforms where maintenance tasks or challenges are presented interactively and unpredictably, for example, a digital tool that offers daily ‘surprise’ maintenance tips or challenges can keep the work interesting.

- Rotating Roles and Responsibilities: Rotate roles and responsibilities within the maintenance team at irregular intervals, breaking the monotony and encouraging a broader understanding of different aspects of maintenance.

- Unpredictable Collaborations: Create opportunities for unexpected collaborations, such as teaming up with other departments for joint maintenance initiatives, encouraging exchanging ideas, and fostering a sense of community.

- Feedback and Exploration: Encourage a feedback culture where employees can openly share their ideas and suggestions. Explore these ideas, even if they seem unconventional, to foster a culture of innovation and curiosity.

Conclusion

By applying the ‘Unpredictability & Curiosity’ drive from the Octalysis Framework, maintenance strategies within chemical processing plants can evolve from routine procedures into exciting, engaging activities. This approach enhances the effectiveness of maintenance tasks and fosters a work environment where curiosity, innovation, and continuous learning are integral. Such a strategy ensures that maintenance teams remain engaged, motivated, and ready to take on the challenges of maintaining complex chemical processing systems with enthusiasm and creativity.

To learn directly from Yu-Kai’s site:

The information in this article was partially generated by OpenAI’s ChatGPT, an AI language model, and has been reviewed/edited for accuracy and relevance. OpenAI. (2024). ChatGPT [Large language model]. Retrieved from https://chat.openai.com/

Leave a comment