Image from https://yukaichou.com/gamification-examples/octalysis-complete-gamification-framework/

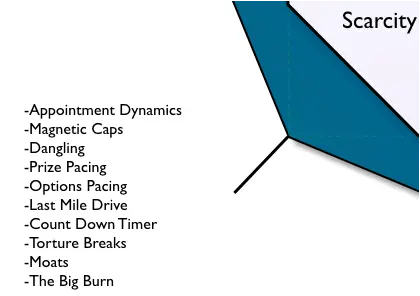

Implementing effective occupational health and safety processes is a top priority in chemical processing plants’ complex and potentially hazardous environments. Gamification, as conceptualized in the Octalysis Framework by Yu-kai Chou, offers a novel approach to enhancing these processes. This blog post explores the application of the “Scarcity and impatience” core drive from this framework to reinforce safety practices in a chemical processing setting.

Understanding “Scarcity & Impatience”

The “Scarcity and impatience” core drive in the Octalysis Framework taps into the human tendency to place a higher value on scarce things and to desire them more when they are not immediately available, heightening awareness and adherence to safety protocols.

- Limited-Time Safety Initiatives: Introduce safety initiatives available for a limited time. For instance, a special training session only open for a few days creates a sense of urgency, encouraging employees to participate promptly.

- Exclusive Safety Rewards: Develop a rewards system where specific safety achievements unlock exclusive benefits. These could be special access to advanced training programs or limited-edition safety gear. The exclusivity of these rewards can drive greater participation and commitment.

- Countdowns to Safety Milestones: Implement countdowns to significant safety milestones, like achieving a certain number of days without an incident. This visible reminder can create a sense of urgency and collective effort to reach the goal.

- Timed Safety Challenges: Organize timed safety challenges where employees must complete specific tasks within a set period, including identifying potential hazards or completing safety checklists. The time-bound nature of these challenges can spur quick action and engagement.

- Early Access to Safety Innovations: Offer early access to new safety equipment or protocols to employees who have demonstrated exemplary safety practices, rewarding top performers and creating a desire to achieve similar recognition.

- Periodic Safety Surveys: Conduct regular safety surveys and only provide feedback to those participating. This method can pique interest and prompt employees to engage more actively with safety practices to receive feedback.

The Impact of “Scarcity & Impatience”

Implementing “Scarcity & Impatience” in occupational health and safety processes can lead to:

- Increased Participation: Creating a sense of urgency and exclusivity can drive higher participation in safety programs.

- Heightened Safety Awareness: The time-bound nature of specific initiatives can keep safety in mind for employees.

- Boosted Morale and Motivation: Exclusive rewards and recognition can boost morale and motivate employees to adhere to safety protocols.

Conclusion

Applying the “Scarcity and impatience” core drive from the Octalysis Framework to the occupational health and safety processes in chemical processing plants offers a unique way to enhance engagement and compliance by leveraging the human response to scarcity and the desire for immediate satisfaction, transforming safety practices into more dynamic and engaging activities. This approach reinforces the importance of safety and contributes to creating a more alert and responsive safety culture within the plant.

To learn directly from Yu-Kai’s site:

The information in this article was partially generated by OpenAI’s ChatGPT, an AI language model, and has been reviewed/edited for accuracy and relevance. OpenAI. (2024). ChatGPT [Large language model]. Retrieved from https://chat.openai.com/

Leave a comment