Image from https://yukaichou.com/gamification-examples/octalysis-complete-gamification-framework/

Occupational health and safety are critical in chemical processing plants, with high risks and severe consequences. Utilizing gamification to enhance safety engagement can be a transformative approach. The Octalysis Framework, created by Yu-kai Chou, provides a multi-faceted model to gamify such processes. The “Loss & Avoidance” core drive can be particularly effective in this context. This blog post explores the application of this principle to reinforce safety protocols in a chemical processing environment.

Understanding “Loss & Avoidance”

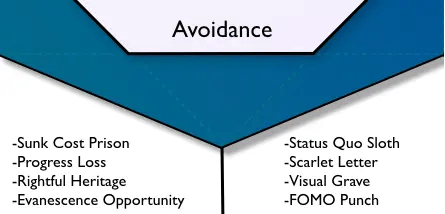

The “Loss and avoidance” core drive in the Octalysis Framework concerns the human desire to avoid adverse outcomes, encourages adherence to safety protocols, and mitigates risks in a chemical processing plant.

- Safety Points System: Implement a safety points system where employees start with a certain number of points and lose points for safety infractions. This system creates a tangible consequence for not following safety protocols, incentivizing employees to avoid losing points.

- Virtual Safety Scenarios: Develop virtual simulations of potential safety incidents. These scenarios can help employees understand the consequences of unsafe behavior and the importance of adhering to safety protocols to avoid adverse outcomes.

- Safety Streaks: Encourage maintaining safety streaks. For example, celebrating a certain number of days without a safety incident. Breaking the streak would mean starting over, which employees naturally want to avoid.

- Loss Aversion in Training: Incorporate loss aversion into safety training. For instance, during a training session, teams could lose points or privileges for incorrect responses or actions, emphasizing the importance of correct safety practices.

- Conditional Access Based on Safety Compliance: Link access to certain benefits or privileges in the plant to safety compliance. For instance, access to more advanced equipment or specialized training could be contingent upon maintaining a good safety record.

- Real-Time Feedback on Safety Risks: Provide real-time feedback on safety risks. For example, when not following a safety measure, an immediate notification can serve as a reminder to avoid the potential loss of safety or efficiency.

The Impact of “Loss & Avoidance”

Applying “Loss & Avoidance” to occupational health and safety can lead to:

- Increased Safety Compliance: The desire to avoid losing points or breaking streaks can lead to more consistent adherence to safety protocols.

- Heightened Risk Awareness: Employees become more aware of the consequences of unsafe practices, leading to more risk-averse behavior.

- Reinforced Safety Behaviors: Avoiding adverse outcomes reinforces positive safety behaviors over time.

Conclusion

Integrating the “Loss & Avoidance” core drive from the Octalysis Framework into chemical processing plants’ occupational health and safety processes offers a unique strategy to bolster safety compliance. By tapping into the natural human instinct to avoid loss and adverse outcomes, this approach not only makes safety protocols more engaging but also ingrains a deeper understanding and commitment to safety among employees. Such a proactive and psychologically informed approach contributes to creating a safer and more responsible working environment in the demanding context of chemical processing.

To learn directly from Yu-Kai’s site:

The information in this article was partially generated by OpenAI’s ChatGPT, an AI language model, and has been reviewed/edited for accuracy and relevance. OpenAI. (2024). ChatGPT [Large language model]. Retrieved from https://chat.openai.com/

Leave a comment