Image from https://yukaichou.com/gamification-examples/octalysis-complete-gamification-framework/.

Introduction

Incorporating motivational frameworks can improve efficiency and employee satisfaction in supply chain management, especially within chemical processing plants. One such framework is the Octalysis, created by Yu-kai Chou, which identifies core drives that motivate human behavior. A particularly relevant drive for this industry is “Development & Accomplishment.” This blog post explores how this concept can be applied to enhance the supply chain processes in chemical processing plants.

The Essence of Development & Accomplishment

“Development & Accomplishment,” the second core drive in the Octalysis Framework, is centered on the internal motivation derived from making progress, developing skills, and overcoming challenges. In a chemical processing plant’s supply chain, development & accomplishment can foster a culture of continuous improvement and achievement.

Strategies for Implementation

- Setting Clear Goals and Milestones: Establish clear, achievable goals for different supply chain stages, including targets for production efficiency, reduction in waste, or timely delivery. Achieving these goals should be recognized and celebrated, giving employees a sense of accomplishment.

- Skill Development Programs: Implement training programs that improve employees’ job performance and equip them with new skills. This approach enhances the supply chain efficiency while contributing to the employee’s personal growth, increasing their engagement and satisfaction.

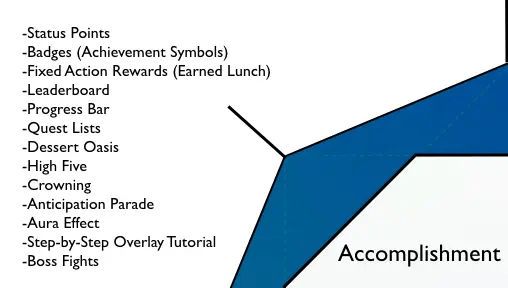

- Gamification of Tasks: Introduce gamified elements in everyday tasks. For example, we create leaderboards for the most efficient teams or award badges for zero-accident weeks. Gamification can make routine tasks more engaging and highlight accomplishments tangibly.

- Feedback and Improvement Cycles: Regular feedback sessions where employees discuss challenges and achievements can foster an environment where continuous improvement is valued and achievements are acknowledged.

- Empowering Employees to Innovate: Encourage employees to suggest improvements in the supply chain process. Recognizing and implementing these suggestions improves the process and gives employees a sense of ownership and accomplishment.

Challenges and Considerations

While implementing these strategies, ensuring that goals are realistic and achievements are genuinely acknowledged is crucial. Unrealistic targets or hollow recognitions can lead to demotivation. Additionally, the unique challenges of the chemical industry, such as safety concerns and regulatory compliance, should always be considered.

Conclusion

Applying the “Development & Accomplishment” drive of the Octalysis Framework to supply chain management in chemical processing plants offers a pathway to enhance both efficiency and employee engagement. Organizations can create a more motivated workforce and a more effective supply chain by fostering an environment where progress, skill development, and achievements are valued. As the industry evolves, embracing innovative approaches will be vital to staying competitive and ensuring a satisfied and dedicated workforce.

To learn directly from Yu-Kai’s site:

Leave a comment