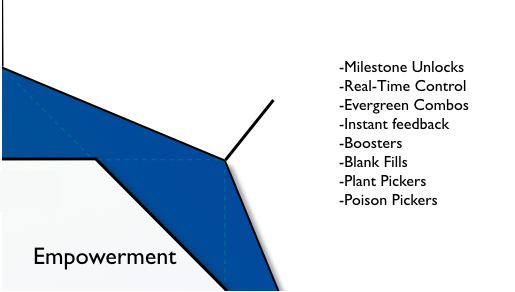

Image from https://yukaichou.com/gamification-examples/octalysis-complete-gamification-framework/

Introduction

Empowerment, hands-off leadership, but with the scaffold. Yeah, we all know the risk of too little hands-on and the pain & effort of being too hands-on. The question is, what can be done about providing handrails to guide creativity and constant feedback that helps our business while being hands-off?

In the landscape of supply chain management within the chemical processing industry, creative problem-solving and innovation are more critical than ever. Here, the Octalysis Framework, designed by Yu-kai Chou, offers a unique lens to view and enhance employee engagement.

Exploring Empowerment of Creativity & Feedback

This core drive in the Octalysis Framework is about enabling and encouraging individuals to express their creativity and see the results of their input. Supply chain management in chemical processing plants leads to innovative ideas, solutions, and a more agile response to challenges.

Strategies for Implementation

- Idea Generation Platforms: Establish platforms where employees can freely share innovative ideas for improving supply chain processes, e.g., a digital suggestion box or regular brainstorming sessions. The key is to create a safe space where all ideas are valued and considered.

- Rapid Prototyping and Experimentation: Implement a system where promising ideas are quickly prototyped and tested. This approach validates the workforce’s creativity and leads to practical, innovative solutions that enhance supply chain efficiency.

- Regular Feedback Loops: Create mechanisms for providing regular, constructive feedback on the ideas and initiatives employees propose. This feedback should be timely, specific, and aimed at helping employees refine their ideas and understand their impact.

- Cross-functional collaboration: Encourage collaboration across different departments. For instance, joint projects between supply chain management, production, and R&D teams can lead to a more holistic approach to innovation in the plant.

- Recognition and Reward Systems: Acknowledging and rewarding creative contributions and successful practices introduced by individual contributors motivates them and promotes the organization’s innovation culture.

Challenges and Considerations

Implementing this core drive requires a delicate balance. We need to manage risks associated with experimentation, especially in the sensitive environment of a chemical processing plant. Moreover, fostering a culture that genuinely values creativity over a long period requires consistent effort and enforcement from all levels of management.

Conclusion

Incorporating the “Empowerment of Creativity & Feedback” drive from the Octalysis Framework into supply chain management at chemical processing plants can lead to significant advancements in efficiency, problem-solving, and employee engagement. By valuing and implementing creative ideas from the workforce, companies can optimize their supply chain processes and foster a more dynamic, innovative, and motivated organizational culture. As the chemical industry faces new challenges and opportunities, embracing such frameworks will be essential for sustained growth and success.

To learn directly from Yu-Kai’s site:

Leave a comment