Image from https://yukaichou.com/gamification-examples/octalysis-complete-gamification-framework/

Introduction

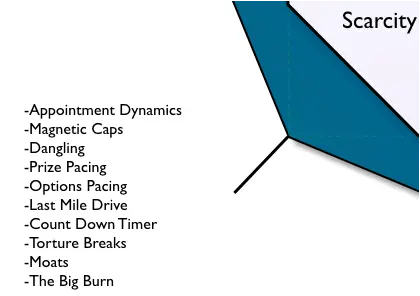

In the intricate and high-stakes environment of chemical processing plants, the efficiency and effectiveness of supply chain management are paramount. Innovative approaches to enhance this efficiency can come from behavioral science, such as the Octalysis Framework by Yu-kai Chou. A particularly intriguing aspect of this framework is the concept of “Scarcity & Impatience.” This blog post explores how applying this principle can significantly optimize supply chain operations in chemical processing environments.

Understanding Scarcity & Impatience

The core drive of “Scarcity and impatience” in the Octalysis Framework revolves around the human response to scarce resources and the desire to obtain them immediately while harnessing “Scarcity and impatience” to create urgency and prioritize efficient use of resources, ultimately leading to more streamlined and dynamic operations.

Strategic Application in Chemical Processing Plants

- Limited-Time Challenges and Goals: Implementing time-bound challenges for supply chain teams can create a sense of urgency and focus. For instance, setting a limited period to achieve specific efficiency targets can motivate teams to work more collaboratively and innovatively.

- Resource Allocation Games: Introduce gamified elements where teams must efficiently manage limited resources to achieve their goals, involving simulations or real-life scenarios where teams strategize on resource utilization under constraints.

- Exclusive Access and Rewards: Create systems where exceptional supply chain performance provides exclusive benefits. These could be early access to new technologies, special training programs, or additional resources for the best-performing teams.

- Visible Countdowns and Trackers: Utilize digital dashboards with countdowns for critical supply chain milestones. This visibility can create a sense of urgency and a constant reminder of goals and timelines.

- Priority-based Task Management: Implement a system where the most critical tasks in the supply chain are highlighted and prioritized. This approach leverages the natural human response to scarcity, focusing attention and resources on the most pressing issues.

Challenges and Considerations

While applying these strategies, it’s crucial to balance the created sense of urgency with the need for safety and accuracy, which is especially important in the chemical processing industry. Ensuring this approach doesn’t lead to burnout or undue employee stress is also essential.

Conclusion

Applying the “Scarcity and impatience” drive from the Octalysis Framework to supply chain management in chemical processing plants presents an opportunity to inject a sense of urgency and efficiency into operations. Companies can foster a more dynamic, focused, innovative supply chain environment by strategically creating scarcity and time-bound challenge scenarios. This approach drives operational excellence and aligns with the chemical processing industry’s fast-paced and constantly evolving nature.

To learn directly from Yu-Kai’s site:

Leave a comment