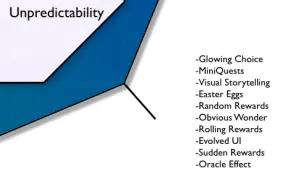

Image from https://yukaichou.com/gamification-examples/octalysis-complete-gamification-framework/

Introduction

The supply chain in a chemical processing plant is a complex and vital component of its operation. Innovative management approaches are essential to enhance efficiency and effectiveness. One such approach is the application of the Octalysis Framework’s “Unpredictability & Curiosity” principle, designed by Yu-kai Chou. This blog post delves into how this concept can improve supply chain management in chemical processing plants.

The Essence of Unpredictability & Curiosity

The “Unpredictability & Curiosity” drive in the Octalysis Framework is about the excitement and engagement from unexpected and novel experiences. In managing supply chains, “Unpredictability and curiosity” encourages creative thinking, adaptability, and continuous learning, which is crucial in the dynamic environment of a chemical processing plant.

Strategies for Implementing Supply Chains

- Randomized Problem-Solving Challenges: Introduce unexpected problem-solving scenarios in training sessions or as part of regular operations. Keep the team alert and ready to think on their feet, fostering a culture of adaptability and quick thinking.

- Rotational Job Assignments: Implement a system where employees periodically switch roles or take on different responsibilities within the supply chain, broadening their skills and maintaining a high level of engagement and curiosity about different aspects of the supply chain.

- Innovation Incubators: Create a space or program where employees can experiment with new ideas and approaches to supply chain management without the pressure of immediate results, leading to innovative solutions and a deeper understanding of the supply chain processes.

- Surprise Rewards and Acknowledgments: Introduce a system of unexpected rewards for outstanding performance or innovative ideas, ranging from recognition in company meetings to bonuses or other incentives.

- Regular Industry Updates and Learning Opportunities: Keep the team informed about the latest trends and technologies in supply chain management. Offer opportunities for learning and experimentation with these new approaches.

Challenges and Considerations

While implementing this principle, it’s essential to balance maintaining the structure and predictability required for a safe and efficient supply chain and introducing elements of unpredictability. We need to ensure that these initiatives do not compromise the safety standards critical in chemical processing plants.

Conclusion

Incorporating the “Unpredictability & Curiosity” drive from the Octalysis Framework into supply chain management in chemical processing plants presents a unique opportunity to foster a culture of continuous improvement, innovation, and adaptability. By introducing elements that keep the workforce engaged, curious, and ready for new challenges, organizations can create a dynamic and efficient supply chain that is well-prepared to handle the complexities and demands of the chemical processing industry.

To learn directly from Yu-Kai’s site:

Leave a comment