Image from https://yukaichou.com/gamification-examples/octalysis-complete-gamification-framework/

Introduction

Managing supply chains effectively is critical in the chemical processing industry, where precision, safety, and efficiency are paramount. Incorporating behavioral science into management strategies can significantly enhance these elements. The Octalysis Framework, created by Yu-kai Chou, offers an innovative approach, mainly through the core drive of “Loss and avoidance.”

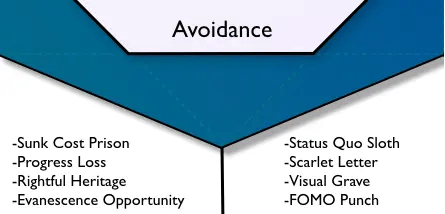

Understanding Loss & Avoidance

The “Loss & Avoidance” drive in the Octalysis Framework focuses on the human tendency to avoid adverse outcomes or the loss of something valuable. The “Loss and avoidance” drive can applied in supply chain management to motivate behaviors that prevent inefficiencies, errors, and safety incidents.

Applying Loss & Avoidance in Supply Chain Management

- Risk Mitigation Incentives: Develop incentive programs that reward teams for maintaining safety standards and minimizing risks. For example, recognizing the most prolonged period without safety incidents or errors in the supply chain can motivate teams to adhere strictly to protocols.

- Deadline-Driven Tasks: Implement strict deadlines for specific supply chain tasks, with clear consequences for missing them, creating a sense of urgency and focusing on meeting timelines to avoid adverse outcomes.

- Accountability Measures: Establish clear accountability structures where teams or individuals are responsible for specific aspects of the supply chain. Knowing they are directly accountable can drive employees to avoid errors and inefficiencies.

- Loss Aversion Training: Conducting training sessions emphasizing the consequences of supply chain failures, such as the impact on safety, cost, or delivery times. Understanding what is at stake can motivate employees to be more vigilant and proactive.

- Regular Audits and Feedback: Implement a system of regular audits for different parts of the supply chain, with feedback on areas needing improvement. The possibility of being audited can act as a deterrent against complacency and negligence.

Challenges and Considerations

While applying the “Loss and avoidance” principle, ensuring that the focus remains positive and constructive is crucial. Overemphasis on adverse outcomes can lead to a stressful work environment and affect morale. Safety should always be the top priority in the chemical processing industry, and any strategies implemented must not compromise it.

Conclusion

Incorporating the “Loss & Avoidance” drive from the Octalysis Framework into supply chain management in chemical processing plants can significantly improve efficiency, safety, and reliability. By leveraging this drive, companies can motivate their workforce to avoid adverse outcomes through proactive and vigilant actions. As the chemical industry continues to navigate complex challenges, such innovative approaches to management will be essential for sustained success and growth.

To learn directly from Yu-Kai’s site:

Leave a comment