Image from https://yukaichou.com/gamification-examples/octalysis-complete-gamification-framework/

Introduction

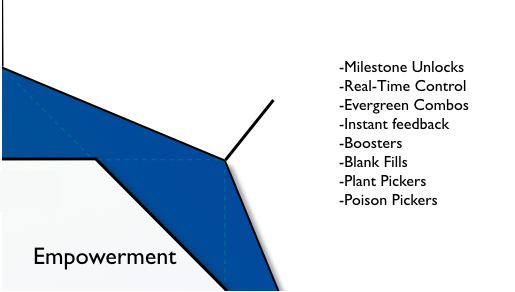

Applying the Octalysis Framework “Empowerment of Creativity & Feedback” to Managing Quality in a Chemical Processing Plant

In the quest for continuous improvement in industrial environments, incorporating innovative motivational frameworks can be transformative. The Octalysis Framework, conceptualized by Yu-kai Chou, provides a multi-faceted approach to enhance employee engagement. One of its core drives, “Empowerment of Creativity & Feedback,” is particularly pertinent to managing quality in a chemical processing plant. This blog post explores how this principle can be effectively applied in such a setting.

Understanding Empowerment of Creativity & Feedback

Empowerment of Creativity & Feedback focuses on giving individuals the freedom to express their creativity and experiment, coupled with immediate feedback on their actions. In a workplace, this translates into allowing employees to innovate and solve problems in new ways, while providing them with real-time, constructive feedback.

Implementation in a Chemical Processing Plant

- Fostering a Creative Environment: Create a work culture that encourages innovative thinking and problem-solving. Encourage employees to think outside the box and challenge the status quo, especially in terms of quality control and process improvement.

- Idea Submission Platforms: Establish platforms where employees can submit ideas for improving quality. This could be a digital suggestion box or regular brainstorming sessions. Ensure that every idea is acknowledged and evaluated.

- Prototype and Experimentation Opportunities: Provide resources and opportunities for employees to develop prototypes or conduct experiments on their improvement ideas. This could involve allocating time for project work or providing access to special equipment.

- Constructive Feedback Mechanism: Develop a system for providing prompt and constructive feedback on the ideas and experiments. This feedback should be geared towards helping employees refine their ideas and learn from the process.

- Rewarding Innovation: Recognize and reward creative solutions that lead to tangible improvements in quality. This could be through awards, bonuses, or even just public acknowledgment in front of peers.

- Learning from Failures: Cultivate an environment where failure is seen as a part of the learning process. Encourage teams to analyze and share lessons from unsuccessful experiments or ideas, ensuring that these are used as stepping stones for future innovation.

- Cross-Departmental Collaboration: Promote collaboration between different departments for broader perspectives on quality issues. This can lead to more comprehensive and innovative solutions.

Challenges and Considerations

- Balancing Creativity with Safety and Regulations: In a chemical processing plant, safety and regulatory compliance cannot be compromised. It’s important to balance creative freedom with these constraints.

- Resource Allocation: Providing resources for experimentation and prototyping can be challenging. It’s crucial to manage these resources effectively to avoid affecting the plant’s regular operations.

- Cultural Shift: Shifting to a culture that fully embraces creativity and rapid feedback might require significant changes in mindset and practices, especially in traditionally conservative industries like chemical processing.

Conclusion

Integrating the “Empowerment of Creativity & Feedback” core drive of the Octalysis Framework into quality management at a chemical processing plant can significantly boost innovation and employee engagement. By creating an environment that values creative thinking, supports experimentation, and provides constructive feedback, employees become more invested in the quality of their work. This not only leads to improvements in processes and products but also fosters a culture of continuous learning and development, crucial for the long-term success of any organization.

To learn directly from Yu-Kai’s site:

The information in this article was partially generated by OpenAI’s ChatGPT, an AI language model, and has been reviewed/edited for accuracy and relevance. OpenAI. (2024). ChatGPT [Large language model]. Retrieved from https://chat.openai.com/

Leave a comment