Image from https://yukaichou.com/gamification-examples/octalysis-complete-gamification-framework/

Introduction:

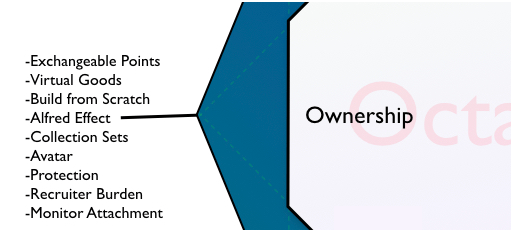

Applying the Octalysis Framework “Ownership & Possession” to Managing Quality in a Chemical Processing Plant

Incorporating gamification principles into workplace management strategies can yield significant improvements in employee engagement and productivity. One such principle, derived from Yu-kai Chou’s Octalysis Framework, is “Ownership & Possession”. This core drive taps into the human desire to own and collect things. In this blog post, we’ll explore how applying this drive can enhance quality management in the context of a chemical processing plant.

Understanding Ownership & Possession

“Ownership & Possession” is about the motivation that comes from owning something and making it one’s own. In a workplace, this can translate into taking responsibility for certain tasks or projects, feeling a sense of pride in one’s work, and being motivated to improve and care for what one is responsible for.

Implementation in a Chemical Processing Plant

- Personal Responsibility for Quality: Assign specific quality-related tasks or areas of the plant to individual employees or teams. This could involve overseeing certain quality control checks, maintaining equipment, or managing specific stages of the production process.

- Empowering Employees with Tools and Resources: Provide employees with the tools, resources, and training needed to excel in their assigned tasks. This not only makes them feel valued but also gives them a sense of ownership over their work.

- Creating a System of Tangible Rewards: Develop a rewards system where employees can earn points, badges, or other incentives for meeting or exceeding quality standards. This system should be transparent and consistently applied.

- Visual Representation of Achievements: Use visual aids like charts, graphs, or leaderboards to display team or individual achievements in quality management. This not only recognizes and motivates employees but also fosters a sense of competition and achievement.

- Encouraging Innovation and Improvement Suggestions: Create channels for employees to suggest improvements to quality processes. When these suggestions are implemented, the contributors should be recognized and rewarded, reinforcing their sense of ownership over the plant’s quality standards.

- Regular Feedback and Progress Tracking: Implement a system for regular feedback, allowing employees to understand how their efforts are contributing to the plant’s overall quality. This feedback should be constructive and aimed at encouraging further improvement.

Challenges and Considerations

- Maintaining Safety and Compliance: While encouraging ownership, it’s crucial to ensure that safety and regulatory compliance are always upheld in a chemical processing plant.

- Balancing Individual and Team Responsibilities: It’s important to strike a balance between individual ownership and teamwork. Quality management is often a team effort, and while individual contributions should be recognized, teamwork should also be encouraged.

- Avoiding Overburdening Employees: Assign responsibilities in a way that doesn’t overburden employees or lead to burnout. Ensure that tasks are evenly distributed and manageable.

Conclusion

Applying the “Ownership & Possession” principle from the Octalysis Framework to managing quality in a chemical processing plant can lead to a more engaged and proactive workforce. By giving employees a sense of ownership over their tasks and the quality of the plant’s outputs, they are likely to take greater pride in their work and be more motivated to maintain high standards. This approach not only improves quality but also contributes to a positive and empowering workplace culture.

To learn directly from Yu-Kai’s site:

The information in this article was partially generated by OpenAI’s ChatGPT, an AI language model, and has been reviewed/edited for accuracy and relevance. OpenAI. (2024). ChatGPT [Large language model]. Retrieved from https://chat.openai.com/

Leave a comment