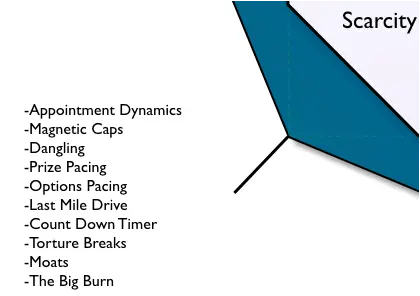

Image from https://yukaichou.com/gamification-examples/octalysis-complete-gamification-framework/

Introduction:

Applying the Octalysis Framework “Scarcity & Impatience” to Managing Quality in a Chemical Processing Plant

The Octalysis Framework, devised by Yu-kai Chou, is a renowned tool in gamification, effectively used to enhance motivation and engagement in various settings. One of its intriguing core drives is “Scarcity & Impatience”, which taps into the human tendency to value things more when they are rare or when obtaining them requires overcoming challenges. This blog post will explore how this principle can be strategically applied to manage and improve quality in a chemical processing plant.

Understanding Scarcity & Impatience

“Scarcity & Impatience” is the desire to have something you can’t have or can only have limited access to. In the workplace, this could translate into exclusive rewards, recognition, or opportunities that are available only to those who meet certain quality standards or performance benchmarks.

Implementation in a Chemical Processing Plant

- Exclusive Rewards for Quality Achievements: Establish a system of rewards that are only available to employees or teams who meet or exceed specific quality goals. These could range from exclusive access to advanced training programs to special recognition events.

- Limited-Time Challenges: Introduce limited-time challenges or competitions focused on quality improvement. For instance, a challenge to reduce waste or improve process efficiency within a specific timeframe. This creates a sense of urgency and excitement around meeting quality goals.

- Progress Levels and Unlockable Content: Implement a tiered system where employees can ‘level up’ by achieving certain quality standards. Each level could unlock new privileges or rewards, such as access to specialized training, advanced equipment, or even involvement in high-profile projects.

- Visibility of Progress and Achievements: Use visual tools like leaderboards or progress trackers to make everyone’s contributions and achievements visible. This not only acknowledges the achievers but also creates a sense of scarcity and desire among others to reach that level.

- Special Roles or Titles: Assign special titles or roles to those who consistently excel in quality management. These roles could come with additional responsibilities or privileges, making them sought-after positions within the plant.

- Feedback Loops: Provide immediate feedback on quality-related performance, allowing employees to understand how close they are to achieving the next level or reward. This feedback should be constructive and aimed at guiding employees towards improvement.

Challenges and Considerations

- Balancing Motivation and Pressure: It’s essential to balance the drive created by scarcity and impatience with the potential pressure it might put on employees. Goals should be challenging yet achievable to avoid stress and burnout.

- Maintaining Fairness and Transparency: Ensure that the system for rewards and recognition is fair and transparent. All employees should have an equal opportunity to participate and be recognized.

- Aligning with Overall Plant Goals: Any scarcity and impatience mechanisms should align with the broader goals and safety standards of the plant. Quality improvements should not compromise safety or regulatory compliance.

Conclusion

Integrating the “Scarcity & Impatience” principle from the Octalysis Framework into quality management at a chemical processing plant can create a more dynamic and engaging work environment. By setting up exclusive rewards, time-limited challenges, and visible progress markers, employees are incentivized to focus on and improve quality standards. This not only leads to tangible improvements in plant operations but also fosters a culture of continuous improvement and excellence.

To learn directly from Yu-Kai’s site:

The information in this article was partially generated by OpenAI’s ChatGPT, an AI language model, and has been reviewed/edited for accuracy and relevance. OpenAI. (2024). ChatGPT [Large language model]. Retrieved from https://chat.openai.com/

Leave a comment