Image from https://yukaichou.com/gamification-examples/octalysis-complete-gamification-framework/

Introduction:

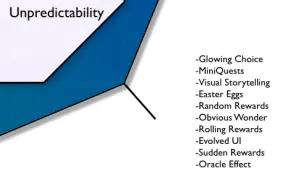

Applying the Octalysis Framework “Unpredictability & Curiosity” to Managing Quality in a Chemical Processing Plant

In the realm of employee engagement and motivation, gamification strategies have proven to be highly effective. One such strategy is derived from Yu-kai Chou’s Octalysis Framework, specifically the core drive of “Unpredictability & Curiosity.” This drive taps into the human love for surprises and the unknown. Applying this principle to manage and enhance quality in a chemical processing plant can lead to innovative and engaging approaches. Let’s delve into how this can be achieved.

Understanding Unpredictability & Curiosity

“Unpredictability & Curiosity” stems from the human desire for novelty and surprise. In a work setting, it can be harnessed to create a dynamic environment where employees are continually engaged and motivated by new challenges and discoveries.

Implementation in a Chemical Processing Plant

- Randomized Quality Audits and Rewards: Introduce random quality audits where excellent performance can lead to unexpected rewards. This keeps employees on their toes, always striving for high quality in anticipation of these audits.

- Mystery Tasks or Challenges: Occasionally introduce mystery tasks or challenges related to quality improvement. These could be puzzles or problem-solving activities that require creative thinking and collaboration.

- Rotating Responsibility Roles: Implement a system where employees rotate through different quality-related roles or tasks. This rotation not only broadens their skill set but also adds an element of variety and learning to their routine.

- Surprise Learning Sessions: Organize impromptu learning sessions or workshops on topics related to quality management, safety, or new technologies. Keeping the topics a surprise adds an element of curiosity and excitement.

- Innovation Labs: Set up ‘innovation labs’ where employees can experiment with new ideas for improving quality. These labs can be spaces for creative thinking without the pressure of immediate practical application.

- Gamified Learning and Development: Incorporate elements of gamification into training programs. Use quizzes, simulations, and interactive modules that have unpredictable outcomes based on user choices.

Challenges and Considerations

- Maintaining Consistency and Focus: While unpredictability can be engaging, it’s important to maintain a consistent focus on the core objectives of quality management.

- Balancing Novelty with Routine: In a chemical processing plant, routine and procedures are often critical for safety and efficiency. Balancing the new and unexpected with these routines is crucial.

- Ensuring Participation and Inclusivity: Make sure that these initiatives are inclusive and that all employees have the opportunity to participate and benefit from them.

Conclusion

Applying the “Unpredictability & Curiosity” principle from the Octalysis Framework in a chemical processing plant can invigorate the quality management process. By introducing elements of surprise, novelty, and continuous learning, employees remain engaged and motivated. This approach not only enhances the quality of work but also contributes to a dynamic and innovative workplace culture. It’s a strategy that goes beyond conventional methods, tapping into the innate human love for challenges and new experiences.

To learn directly from Yu-Kai’s site:

The information in this article was partially generated by OpenAI’s ChatGPT, an AI language model, and has been reviewed/edited for accuracy and relevance. OpenAI. (2024). ChatGPT [Large language model]. Retrieved from https://chat.openai.com/

Leave a comment