Image from https://yukaichou.com/gamification-examples/octalysis-complete-gamification-framework/

Introduction:

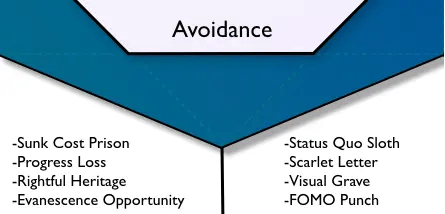

Applying the Octalysis Framework “Loss & Avoidance” to Managing Quality in a Chemical Processing Plant

The Octalysis Framework, designed by Yu-kai Chou, offers a unique approach to gamification in the workplace, focusing on driving human behavior through different core drives. One such drive is “Loss & Avoidance,” which leverages the human instinct to avoid negative outcomes. This blog post will explore how the principle of Loss & Avoidance can be applied to enhance quality management in a chemical processing plant.

Understanding Loss & Avoidance

“Loss & Avoidance” is based on the psychological principle that people are often more motivated to avoid a loss than to achieve a gain. In a workplace setting, this can translate into strategies that focus on preventing negative consequences, such as safety incidents or quality lapses.

Implementation in a Chemical Processing Plant

- Establish Clear Consequences for Quality Failures: Clearly communicate the potential negative outcomes of not adhering to quality standards, such as safety risks, environmental impact, or financial losses. This understanding can motivate employees to maintain high-quality standards.

- Implement a Quality Points System: Introduce a points system where employees start with a certain number of points and lose points for quality infractions. This system should be fair and transparent, with a focus on education and improvement.

- Regular Quality Audits with Visible Outcomes: Conduct regular audits and make the results visible to all employees. The possibility of having their results displayed can motivate teams to maintain high standards to avoid the negative attention that comes with poor audit results.

- Time-Bound Challenges to Prevent Quality Slippage: Set up time-bound challenges where teams must maintain a certain level of quality to avoid negative outcomes, like additional training sessions or loss of certain privileges.

- Negative Reinforcement through Training and Education: Use training sessions not just to educate but also to highlight the consequences of poor quality, such as case studies on accidents or incidents caused by quality lapses.

- ‘Near-Miss’ Reporting and Recognition: Encourage reporting of near-misses in quality. Recognize and reward these reports, as they provide opportunities to correct issues before they lead to actual loss.

Challenges and Considerations

- Balancing Negative and Positive Motivation: While Loss & Avoidance can be a powerful motivator, it’s important to balance it with positive reinforcement. Too much focus on negative outcomes can lead to a fear-based culture.

- Ensuring Fair and Consistent Application: Any system based on Loss & Avoidance must be applied fairly and consistently. Inconsistent application can lead to resentment and a lack of trust in the system.

- Focusing on Learning and Improvement: The goal of implementing Loss & Avoidance strategies should be focused on learning and continuous improvement, rather than punishment or blame.

Conclusion

Integrating the “Loss & Avoidance” drive from the Octalysis Framework into quality management at a chemical processing plant can be an effective way to enhance quality and safety. By clearly outlining the negative consequences of poor quality and creating systems that motivate employees to avoid these outcomes, plants can maintain high standards. However, it’s crucial to balance this approach with positive reinforcement and a focus on learning and continuous improvement to ensure a healthy and productive work environment.

To learn directly from Yu-Kai’s site:

The information in this article was partially generated by OpenAI’s ChatGPT, an AI language model, and has been reviewed/edited for accuracy and relevance. OpenAI. (2024). ChatGPT [Large language model]. Retrieved from https://chat.openai.com/

Leave a comment