Image from https://yukaichou.com/gamification-examples/octalysis-complete-gamification-framework/

Introduction:

In the high-stakes environment of a chemical processing plant, where safety and efficiency are paramount, motivating employees to adhere to protocols and strive for excellence can be challenging. Gamification, a strategy that introduces game-like elements into non-game contexts, offers an innovative solution. Yu-kai Chou’s Octalysis Framework, particularly the “Loss & Avoidance” core drive, provides a compelling approach to enhancing operations and production in this sector.

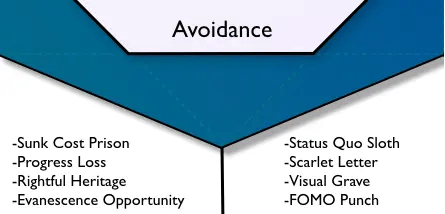

Understanding Loss & Avoidance

The “Loss & Avoidance” drive in the Octalysis Framework capitalizes on the human tendency to avoid adverse outcomes or losing something of value. This can be strategically applied in a chemical processing plant to reinforce safety standards, improve efficiency, and minimize errors.

Strategies for Implementation

- Safety Milestone Rewards: Implement a system where teams are rewarded for reaching safety milestones, such as a certain number of days without incidents. The loss to avoid here is the breaking of this safety streak.

- Efficiency Challenges: Set up challenges where teams are encouraged to improve efficiency in their processes. The loss could be missing recognition or rewards for not meeting these efficiency goals.

- Maintenance Schedules with Alerts: Use a system that alerts teams when equipment maintenance is due. The potential loss here is equipment failure or downtime, which teams naturally want to avoid.

- Peer Accountability Programs: Create a culture where peers hold each other accountable for safety and efficiency. The avoidance is the potential loss of respect or standing within the team for not adhering to standards.

- Continuous Improvement Incentives: Offer incentives for identifying and implementing process improvements. The loss avoided is the missed opportunity to improve operations and gain recognition.

Benefits

Employing the “Loss & Avoidance” drive in a chemical processing plant can bring about several key benefits:

- Enhanced Safety Culture: The focus on avoiding adverse outcomes can significantly strengthen adherence to safety protocols.

- Improved Operational Efficiency: Motivating teams to avoid losses in efficiency encourages constant vigilance and innovation in process optimization.

- Increased Employee Engagement: The challenge of avoiding loss or adverse outcomes can be a powerful motivator, keeping employees more engaged.

- Fosters Responsibility and Accountability: This approach encourages a sense of responsibility and accountability among team members.

Conclusion

Integrating the “Loss & Avoidance” core drive from the Octalysis Framework into the operations and production of a chemical processing plant offers a unique angle to motivate and engage employees. Plants can avoid adverse outcomes by enhancing their safety culture, improving operational efficiency, and fostering a more responsible and accountable workforce. Though centered around loss avoidance, this gamification strategy can significantly improve overall plant performance and employee satisfaction.

To learn directly from Yu-Kai’s site:

The information in this article was partially generated by OpenAI’s ChatGPT, an AI language model, and has been reviewed/edited for accuracy and relevance. OpenAI. (2024). ChatGPT [Large language model]. Retrieved from https://chat.openai.com/

Leave a comment