In the retail world, the “Mystery Shopper” is a legendary tool.

A stranger walks into a store. They act like a normal customer. The staff doesn’t know they are being evaluated.

The result? The staff is always on their toes, providing their best service just in case this customer is the spy.

Now, look at your manufacturing plant.

Your Quality Control (QC) audits are the opposite of a mystery.

They are predictable.

- “The auditor comes every Tuesday at 10 AM.”

- “The clipboard check happens at the start of every shift.”

When inspections are predictable, you suffer from the Hawthorne Effect: People improve their behavior only when they know they are being watched.

When the auditor leaves, the behavior reverts.

Your current QC system is likely driven by Core Drive 8: Loss & Avoidance—the fear of getting caught.

To get true quality, we need to switch to Core Drive 7: Unpredictability & Curiosity.

We need to bring the Mystery Shopper onto the factory floor.

The Psychology: The Bored Brain Misses Details

When an operator looks at the same 10,000 widgets going down a conveyor belt every day, their brain goes on autopilot. They stop seeing the individual parts. They only see the “flow.”

Defects slip through because the brain assumes everything is normal.

A predictable audit doesn’t wake up the brain. It just adds anxiety to the boredom.

To wake up the brain, you need to inject randomness. When the brain doesn’t know what will happen next, it pays attention. It becomes Curious.

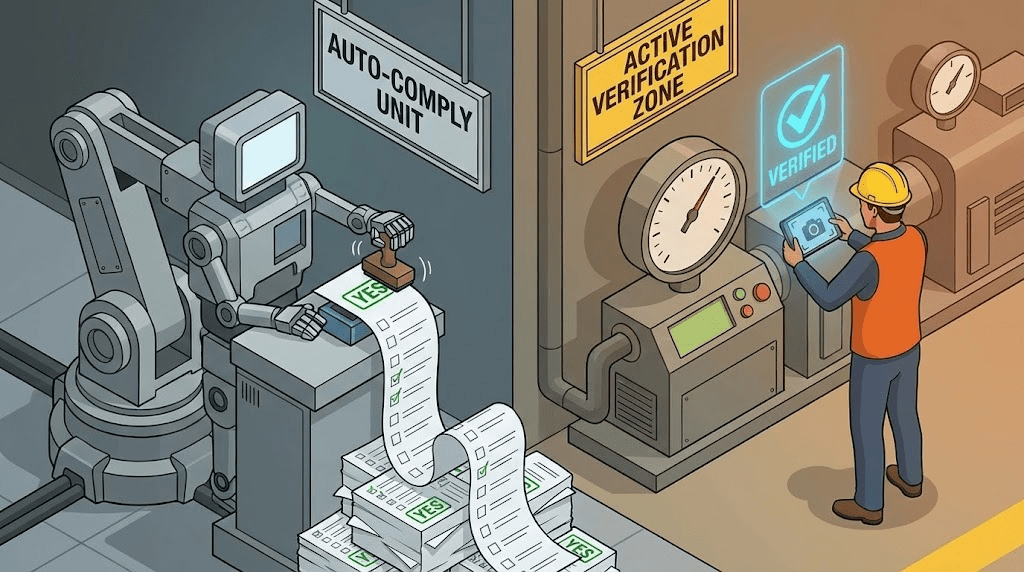

How to Implement “Industrial Mystery Shopping”

You don’t need to hire actors in trench coats. You need to gamify the hunt for defects. Here are two ways to apply Core Drive 7 to your QC process.

1. The “Golden Defect” (Salting the Line)

This is the most direct translation of the Mystery Shopper.

Deliberately introduce a harmless, known defect onto the line.

- Mark a non-critical part with a specific UV pen ink.

- Slightly mislabel an empty box.

Tell the team: “Sometime this week, a ‘Golden Defect’ will pass through this line. The first person to catch it gets a $20 lunch voucher (or social recognition).”

Why it works:

Suddenly, operators aren’t just passively watching parts go by. They are actively Hunting. Their brains are engaged, scanning for the anomaly. In the process of looking for the “fake” defect, they will catch far more real ones.

2. The “Secret Agent” Auditor

Stop sending the same QC manager at the same time.

Deputize other employees to do random spot checks.

- Send an accountant down to check packaging labels.

- Send a warehouse manager to check machine settings.

Why it works:

First, it introduces unpredictability. The line operators don’t know who is checking or when.

Second, “fresh eyes” see things that experienced eyes miss. The accountant might ask, “Why do you do it that way?” and uncover a quality risk that everyone else accepted as normal.

Conclusion: From Policing to Hunting

Traditional QC feels like policing. It is adversarial.

Mystery Shopping feels like a game. It is collaborative.

When you use curiosity to drive quality checks, you turn your workforce from passive observers into active hunters.

Quality stops being something the “Quality Department” does to them, and starts being something they do for the thrill of the find.

Next Step:

Try the “Golden Defect” tomorrow.

Take one item from your production line. Put a distinct (but removable) sticker on the bottom of it. Put it back at the start of the line.

See how long it takes for someone to find it. If it makes it to the end of the line, you know your current inspection process is broken.

The information in this article was partially generated by Google’s Gemini, an AI language model, and has been reviewed/edited for accuracy and relevance.

Leave a comment