Let’s play a word association game. When I say “ISO 9001,” what is the first word that pops into your head?

- Paperwork?

- Audit?

- Boring?

- Necessary Evil?

Nobody wakes up in the morning, pumps their fist, and yells, “Yes! I get to fill out a Corrective Action Request today!”

For most people, Quality Management Systems (QMS) are a bureaucratic tax. We do them because we have to. They are driven by Octalysis Core Drive 8: Loss & Avoidance (we don’t want to lose the certification).

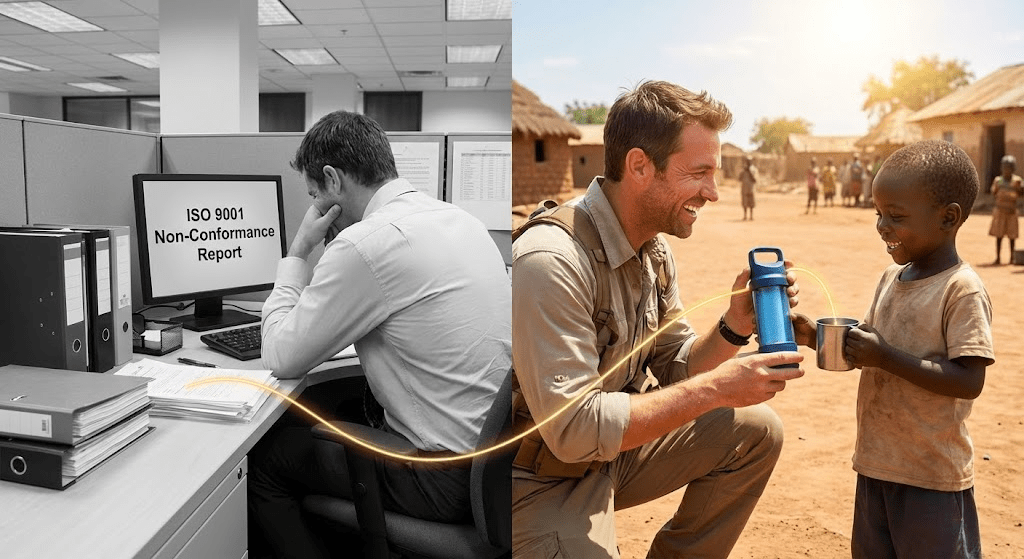

This is a tragedy. Because the purpose of Quality is one of the most noble things a company does.

Quality isn’t about paperwork. It’s about ensuring the brakes on a car don’t fail. It’s about making sure the baby formula is safe. It’s about making sure the medical device saves a life instead of taking one.

The problem isn’t the work; it’s how we frame it. We need to stop talking about “Compliance” and start talking about “Epic Meaning” (Octalysis Core Drive 1).

The “Why” vs. The “What”

Simon Sinek famously said, “Start with Why.”

Most QMS programs start (and end) with “What.”

- The What: “Fill out form QMS-7B in triplicate before shipping the lot.”

- The Why (The Epic Meaning): “Ensure that this pacemaker battery will last for 10 years inside a patient’s chest.”

When an employee is just doing the “What,” they will cut corners. Why wouldn’t they? It’s just paperwork.

When an employee is connected to the “Why,” they become a Guardian. They protect the process because they are protecting the end user.

How to Inject Epic Meaning into Your QMS

You don’t need to change your processes. You just need to change the narrative.

1. The “End User” Connection

Most shop floor workers never see the product after it leaves the loading dock. They are disconnected from the outcome.

The Fix: Bring the outcome to them.

- If you make medical devices, bring a patient who was saved by your product to speak at the all-hands meeting.

- If you make automotive parts, show crash test footage of your airbag deploying and saving a dummy.

When an operator realizes that the “annoying tolerance check” they do every hour is the difference between life and death, they stop complaining and start focusing.

2. Rebrand the Paperwork

Language matters. Stop using soulless corporate jargon.

- Don’t call it a “Non-Conformance Report.” Call it a “Patient Safety Alert.”

- Don’t call it an “Audit.” Call it a “Readiness Drill.”

- Don’t call them “Quality Inspectors.” Call them “Product Guardians.”

It sounds cheesy, but words frame our reality. A Guardian feels a sense of duty that an “Inspector” does not.

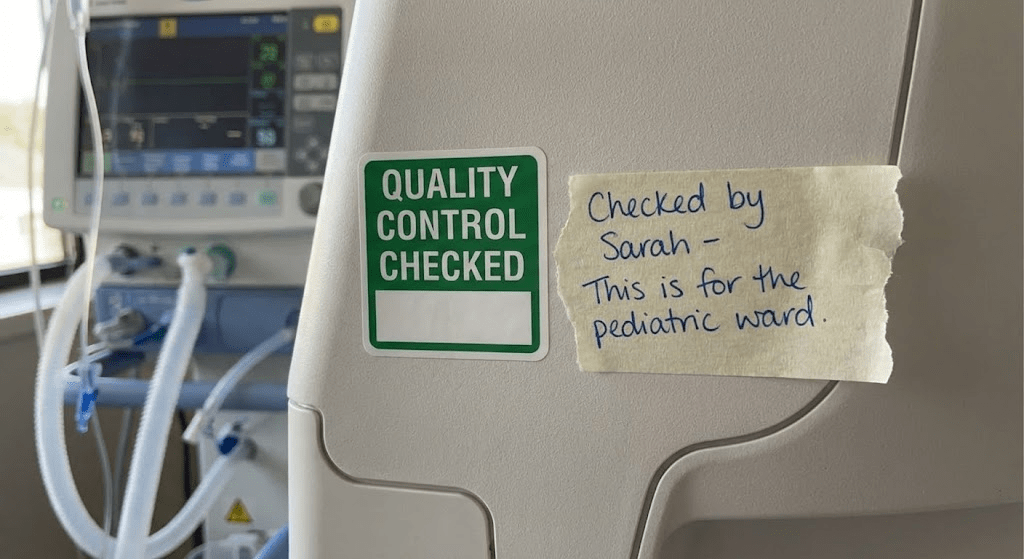

3. The “Signature of Pride”

In the old days, craftsmen would carve their signature into their work. They owned the quality.

Today, we have an anonymous digital checkbox.

The Fix: Bring back the signature.

On the final quality check, don’t just have a digital “Pass.” Have a physical tag where the final inspector signs their name.

The psychological weight of putting your own name on something drives a higher level of care than clicking a button. It says: “I, John Smith, vouch for this product.”

Conclusion: From Bureaucrat to Hero

No one wants to be a bureaucrat. Everyone wants to be a hero.

Your QMS is not a paper-pushing exercise. It is the shield that protects your customers from harm.

It is your job as a leader to remind your team that every time they carefully fill out a form, they aren’t just satisfying an auditor. They are saving the world, one checkbox at a time.

Next Step:

Go to your shop floor. Find a Quality Inspector. Ask them: “What happens to our customers if you don’t do your job today?”

If they answer with “My boss gets mad,” you have work to do.

If they answer with “Someone gets hurt,” you’ve already won.

The information in this article was partially generated by Google’s Gemini, an AI language model, and has been reviewed/edited for accuracy and relevance.

Leave a comment